| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | YOHA |

| Model Number : | YH-EL8 |

| Certification : | CE |

| Price : | Contact Us |

| Payment Terms : | L/C |

| Supply Ability : | Global Supply Available |

Applications:

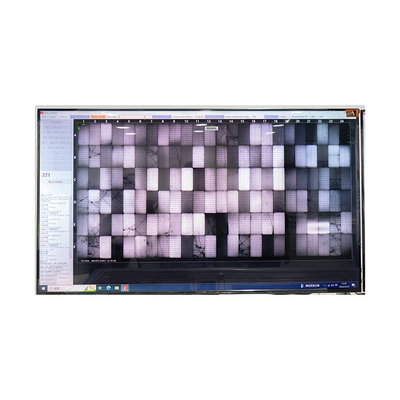

The EL Tester consists of four near-infrared cameras (high quality 0.4mm/pixel), while the AOI Appearance Tester system comprises another four visible light cameras (high quality 0.09mm/pixel). These cameras respectively capture EL infrared images and visible light images, ensuring comprehensive defect detection across both imaging spectra in the solar panel production line.

By utilizing multi-station image acquisition and multi-camera image stitching, the solar cell testing machine generates complete EL Testing and AOI visual images of the solar panel production line. This method guarantees high-resolution imaging, enabling precise defect detection with a small window feature for detailed section analysis. It is essential for accurately identifying both EL Inspection defects, such as hidden cracks and dark spots, and AOI Inspection defects, such as foreign matter and color variations, in solar panel production lines.

The EL Testing and AOI Appearance Testing of PV panels can function either as independent detection systems or be integrated into a single combined detection system. This flexibility of our EL and AOI Appearance Tester allows seamless integration into automated solar panel production lines, ensuring high detection accuracy and efficiency.

Specification:

| Specification | Details |

| Test Items | Various types of solar panels |

| Maximum Field of Vision | 2400mm x 1400mm |

| EL Defect Types | Hidden crack, broken grid, black center, black spot, dark film, debris, etc. |

| AOI Appearance Defects | Foreign matter, damage, exposed white, color difference, etc. |

| Detection Efficiency | Detection time of a single panel: approximately 20.0 seconds |

| Network Communication | Communication between network port and PLC can be integrated with the production line. |

| Program Controlled EL Power Supply | Power parameters can be adjusted through the program. |

| Flexible Formula Type | Compatible with various product models. |

| Database Function | Test results can be saved and queried. |

| Software Interface | Features small window for detailed view; user-friendly and easy to operate. |

| EL Tester | Consists of four near-infrared industrial cameras, four high-definition lenses, filters, and detection software. |

| Appearance Tester | Includes four visible light cameras, four high-definition lenses, light sources, filters, and inspection software. |

Features:

| Feature | Description |

| Special Light Source and Image Acquisition System | Provides stable and high-quality images. |

| Sony CCD Chips | Equipped with high-quality Sony CCD chips for superior image clarity. |

| Image Mosaic | Accurate image mosaic without obvious dislocation. |

| High Detection Efficiency | Ensures high detection efficiency and is easy to integrate with the production line. |

| Intelligent Image Processing Algorithm | Utilizes an intelligent image processing algorithm for stable and reliable detection results. |

| Compatibility with Various Products | Compatible with a variety of products and models, effectively reducing enterprise costs. |

Our Services:

About Us:

Yoha Solar is a high-tech enterprise dedicated to the research,

development, manufacturing, sales, and after-sales service of

serial photoelectric automation equipment.

15+ Years Engaged In Solar

300+ Customers Worldwide

Our company primarily serves the solar photovoltaic industry and

holds its own import and export rights. We have developed a range

of independent R&D equipment.

Main Machinery:Fiber Laser Cutting Machine

Solar cell sorting Machine

Solar Cell IV tester

EL defect tester

EL and AOI Appearance Tester

Solar Panel Production Line

Other Auxiliary Machines

|